When it comes to packaging, selecting the right size box is more than just a detail—it is a key decision that impacts shipping costs, product protection, and customer experience. Whether you need a large shipping box for bulky items or a small shipping box for compact goods, understanding your options can help you make a smart and cost-effective choice.

When to Use a Large Shipping Box

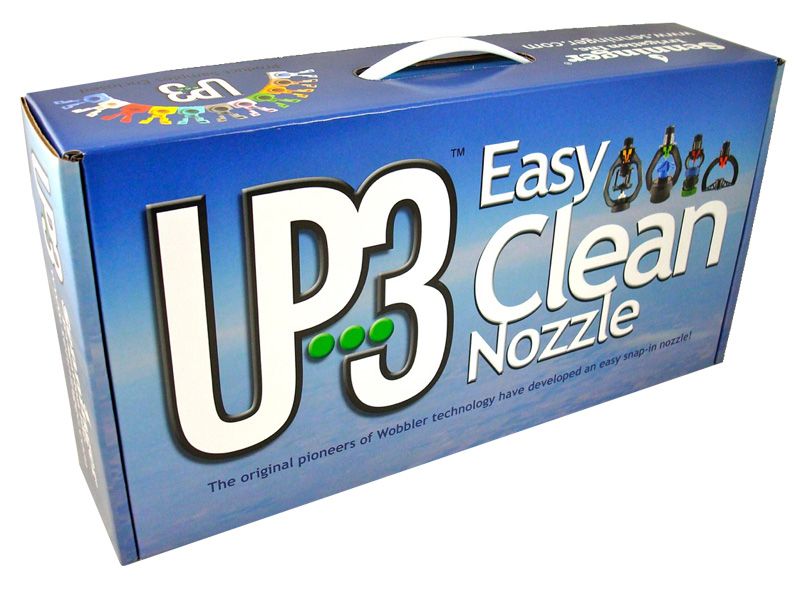

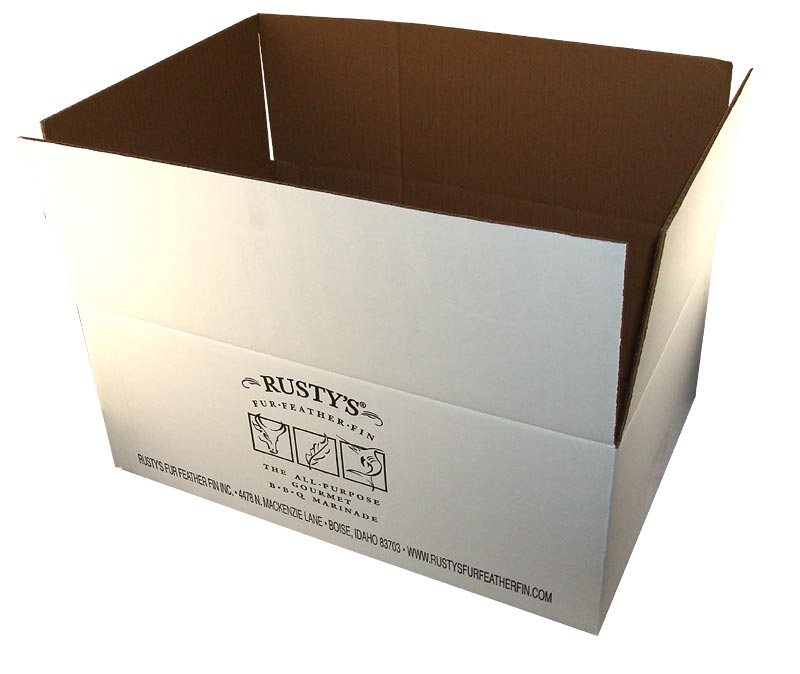

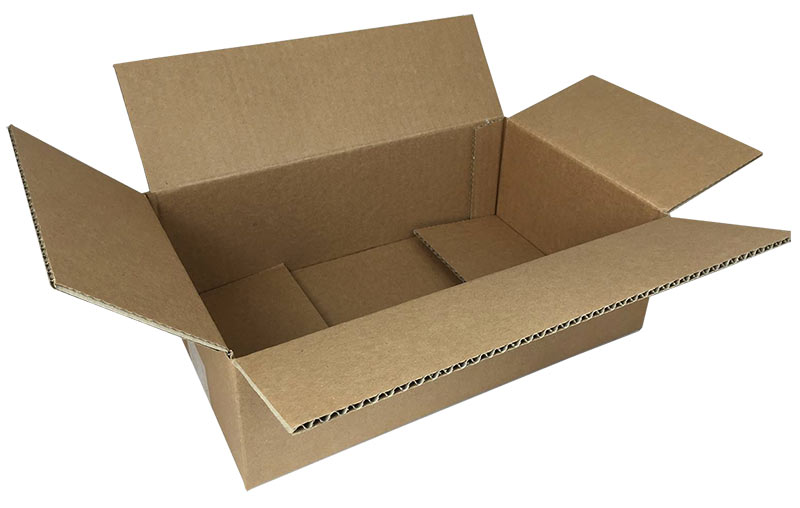

A large shipping box is ideal for oversized, multiple, or oddly shaped items. Products like electronics, bulk orders, or fragile goods that require extra padding often call for larger dimensions. The extra space allows you to add protective materials like foam or air pillows without cramming or risking damage during transit. Additionally, a larger box can consolidate multiple items into one shipment, which may reduce handling and improve efficiency.

However, it is essential not to overuse large boxes. Empty space increases dimensional weight and may lead to higher shipping fees. Choose a box that fits your product snugly, with just enough room for protection.

Why Choose a Small Shipping Box

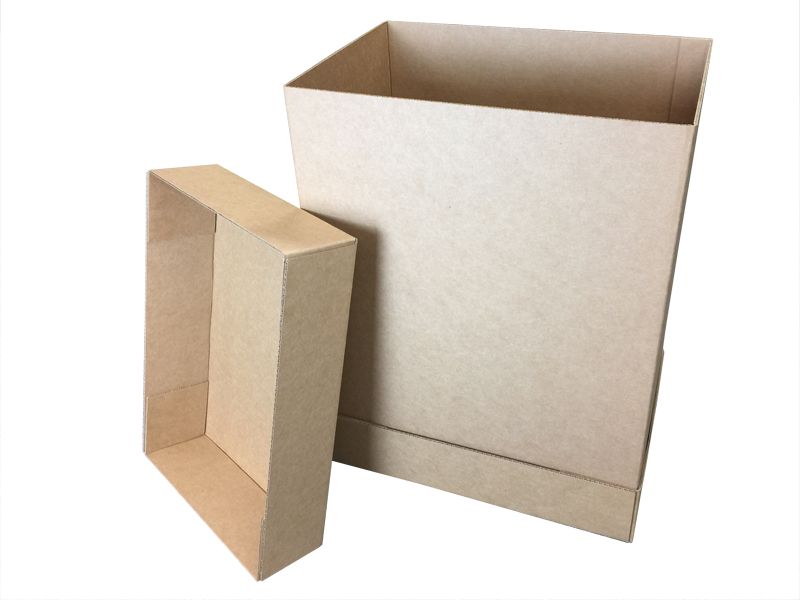

A small shipping box is the go-to for lightweight, individual items such as cosmetics, accessories, small electronics, or stationery. These boxes reduce packaging waste, lower material costs, and help streamline the fulfillment process. They are easier to handle, stack, and store, making them efficient for high-volume shipping operations.

Small boxes are also more eco-friendly. They typically require less filler, use less cardboard, and result in a smaller carbon footprint. In e-commerce, where packaging matters to brand perception, a right-sized small box can enhance the unboxing experience.

Finding the Right Fit for Your Business

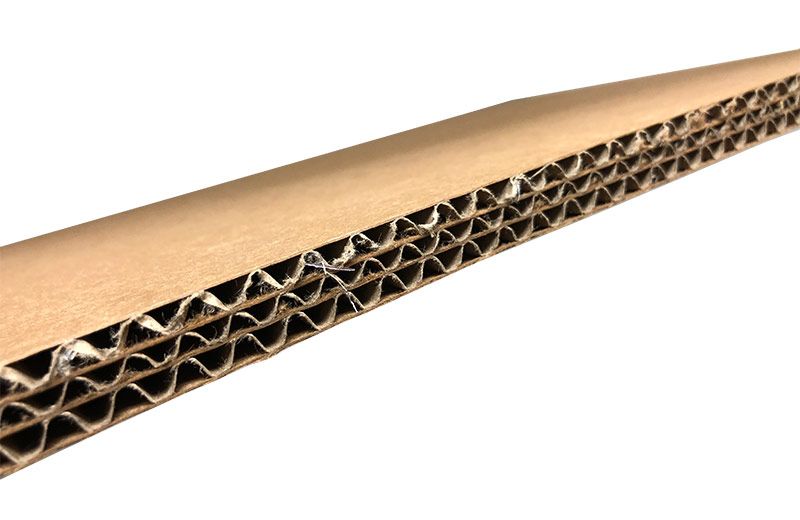

Before selecting a large shipping box or small shipping box, consider your product dimensions, weight, fragility, and delivery method. A well-matched box not only protects your items but also helps reduce shipping costs and improve sustainability. Custom-sized boxes may be a worthwhile investment to optimize your packaging system.

In today’s competitive market, smart packaging is not about the product—it is about the whole customer journey. Choosing the right shipping box size can make a significant difference in how your brand is perceived.

have become a popular trend for order fulfillment. Businesses have increasingly opted to outsource this service to dedicated companies, helping to make their supply chain work more efficiently. They send out a bulk shipment of their products to the

have become a popular trend for order fulfillment. Businesses have increasingly opted to outsource this service to dedicated companies, helping to make their supply chain work more efficiently. They send out a bulk shipment of their products to the