Packaging plays a crucial role in protecting products, enhancing brand appeal, and ensuring a seamless customer experience. Whether you’re an e-commerce retailer, a manufacturer, or a small business owner, finding high-quality cardboard packaging boxes is essential for safe and efficient product delivery. Partnering with a reliable cardboard packaging provider ensures that you receive durable, customizable, and cost-effective solutions tailored to your business needs.

Benefits of Using Cardboard Packaging Boxes

Cardboard packaging is one of the most widely used solutions due to its versatility and eco-friendliness. Here are some of the key benefits:

- Durability & Protection: Cardboard boxes provide a sturdy structure that safeguards products from damage during shipping and handling.

- Sustainability: Most cardboard boxes are recyclable and biodegradable, making them an eco-friendly choice for businesses committed to sustainability.

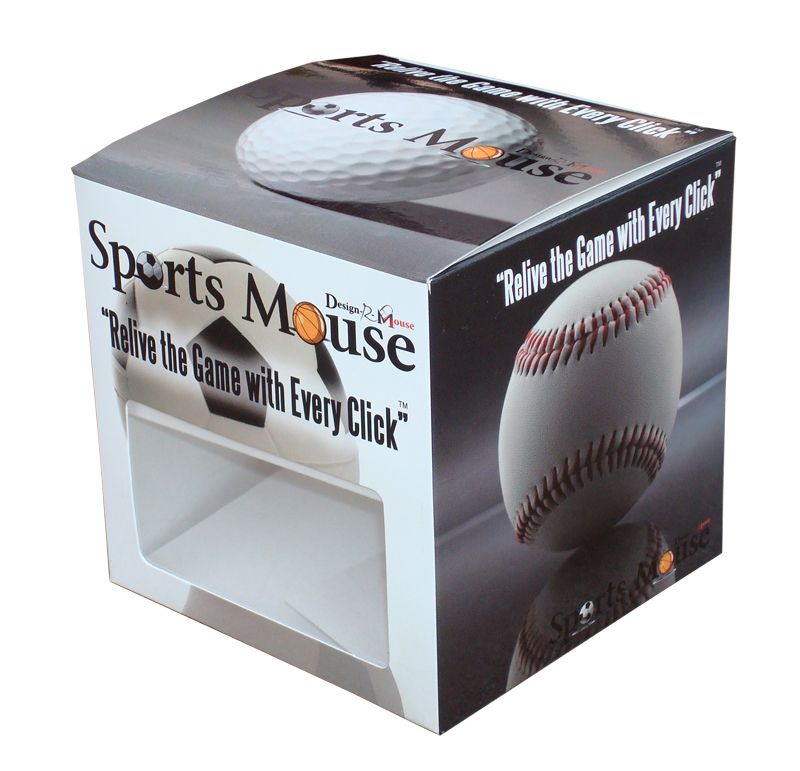

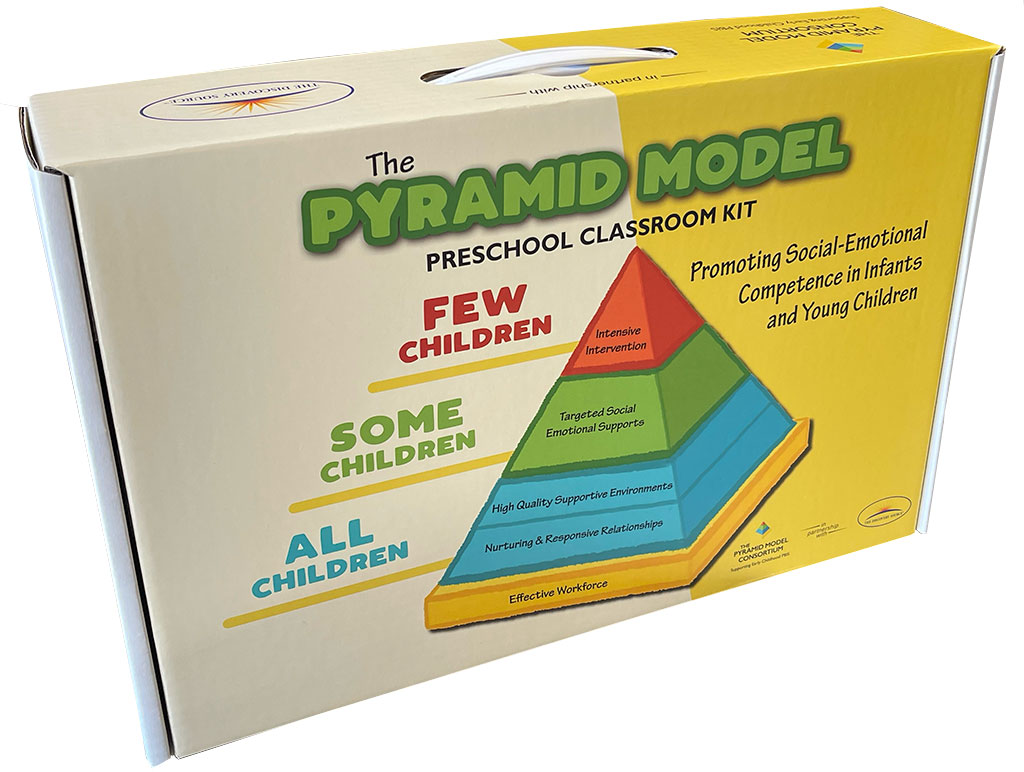

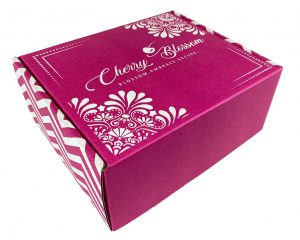

- Customization Options: Businesses can customize boxes with branding, logos, and unique designs to enhance their market presence.

- Cost-Effectiveness: Cardboard packaging is affordable and available in various thicknesses, making it suitable for different product types.

Industries That Benefit from Cardboard Packaging

Cardboard packaging is used across multiple industries due to its adaptability. Some of the sectors that benefit the most include:

- E-Commerce & Retail: Online stores and retail businesses use cardboard boxes for secure product shipments and attractive packaging solutions.

- Food & Beverage: Many food delivery services and manufacturers use food-safe cardboard packaging to maintain freshness and hygiene.

- Electronics & Gadgets: Tech companies package fragile items in specialized cardboard boxes with protective inserts.

- Health & Beauty: Cosmetic and pharmaceutical industries use custom cardboard packaging for branding and product safety.

- Manufacturing & Industrial: Heavy-duty cardboard boxes are used to ship machinery parts and industrial equipment securely.

How to Choose the Right Packaging Provider

Selecting the best packaging provider ensures that your packaging meets industry standards while reflecting your brand identity. Here are some factors to consider:

- Quality & Durability: Ensure the provider offers strong, high-quality cardboard material that suits your product’s needs.

- Customization Capabilities: Look for a supplier that provides custom printing, branding options, and size variations.

- Sustainability Practices: Choose a provider that offers eco-friendly packaging solutions and uses recyclable materials.

- Bulk Pricing & Availability: If your business requires large quantities, check for competitive pricing and fast production times.

- Customer Reviews & Reputation: A reputable provider with positive customer feedback ensures reliability and product satisfaction.

Investing in high-quality cardboard packaging boxes is crucial for businesses looking to enhance product safety and brand identity. Working with a trusted cardboard packaging provider guarantees durable, sustainable, and cost-effective solutions tailored to your business needs.