It is standard practice in the business world to try and limit costs as much as possible to maximize profits. However, many are not as aware of how they can achieve this goal by more efficiently utilizing their shipping & packaging materials. Often, more attention is given to finding a packaging supplier that offers the best deals. Once you have the packaging materials on site, there still needs to be a strategy that will ensure efficiency and minimal waste.

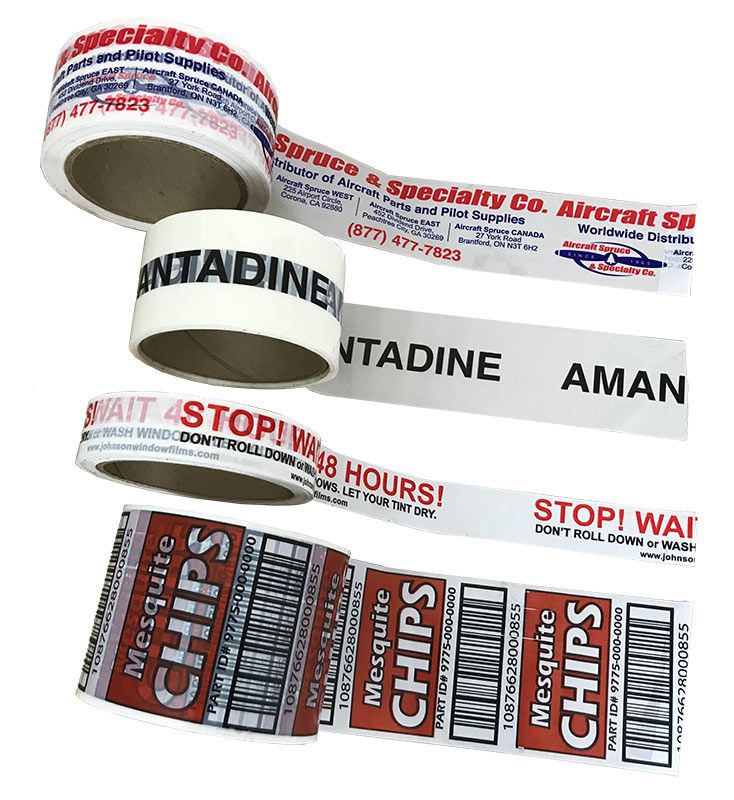

Shipping supplies standardize packing

When designing and sourcing shipping supplies, you will have assessed the product you ship and what you need to ensure they are appropriately packaged and will arrive at their destination safely. It is important to create a standardized procedure that your employees can follow when packaging items for shipping. You can develop checklists and how-to guides that will direct them on how to safely package diverse types of items before they are sent out. This will eliminate confusion, ensure safe packaging, and speed up the shipping process.

Shipping supplies quantity

Keep checking on how much stock you have left of your shipping supplies. Ensure that you have ordered enough supplies well in advance of peak sales periods like Christmas and Black Friday. There may be other peak periods during the year, depending on the nature of your business. You will need more supplies on hand during such periods or risk not being able to send out orders in enjoyable time. Ensure that you place your order for these supplies early enough to avoid overwhelming your supplier when others businesses are making similar orders.

Shipping supplies schedule

Ensure that you give yourself enough time to pick out items ordered, package, label, and ship them out. Do not overwhelm yourself or your employees by insisting on same-day shipping. Be reasonable when setting timelines and ensure that you provide accurate information on your website so your clients are aware of how long this process will take. Too tight a timeline may lead to costly mistakes like poor packaging or mislabeling of boxes. Give yourself enough room to carry out orders in an organized manner.

Organize shipping & packaging materials

It can help to speed up the packing process by pre-packing items that are in the highest demand. That way once an order comes in it is just a matter of labeling and sending it out. You can also place goods that are most ordered close to one another in the same section so they can be quickly picked out for packing.