Within the dominion of packaging, the unacknowledged heroes that contribute to both the protection and presentation of delicate products are dividers. In the context of the growing CBD oil industry, specialized separators take center stage, ensuring that each precious bottle is cradled securely. Join us as we explore the significance of CBD oil dividers in CBD oil packaging, shedding light on the precision and care they bring to the process of safeguarding these valuable products.

The Role of Separators

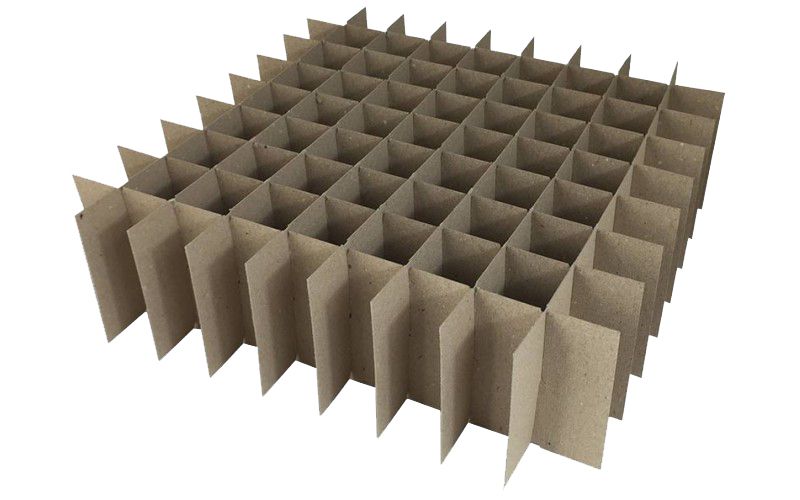

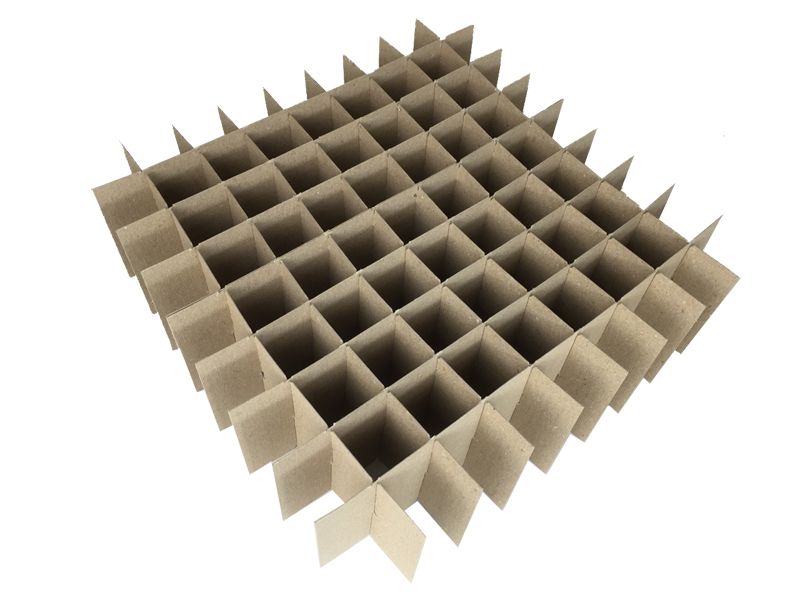

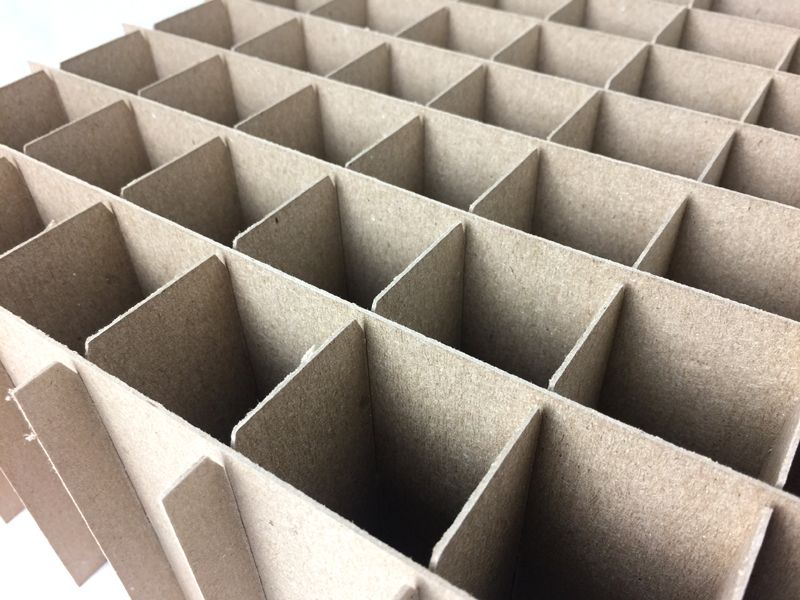

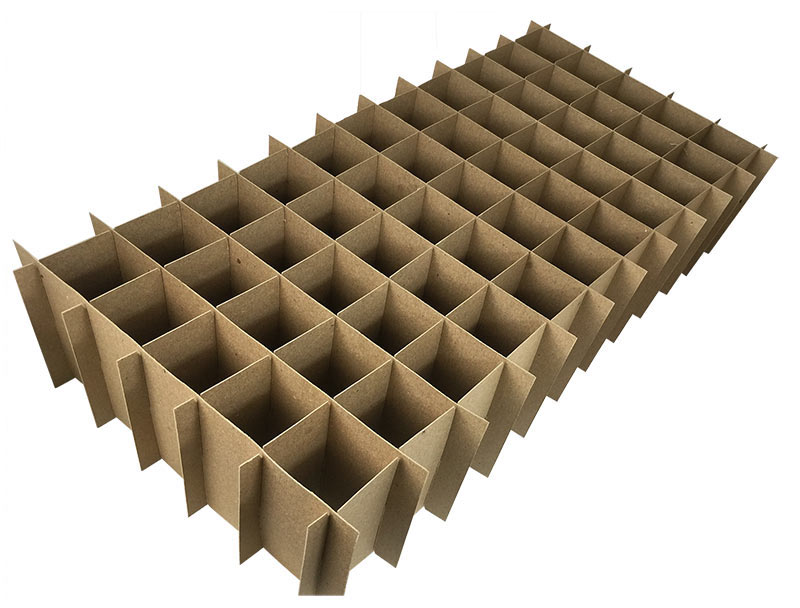

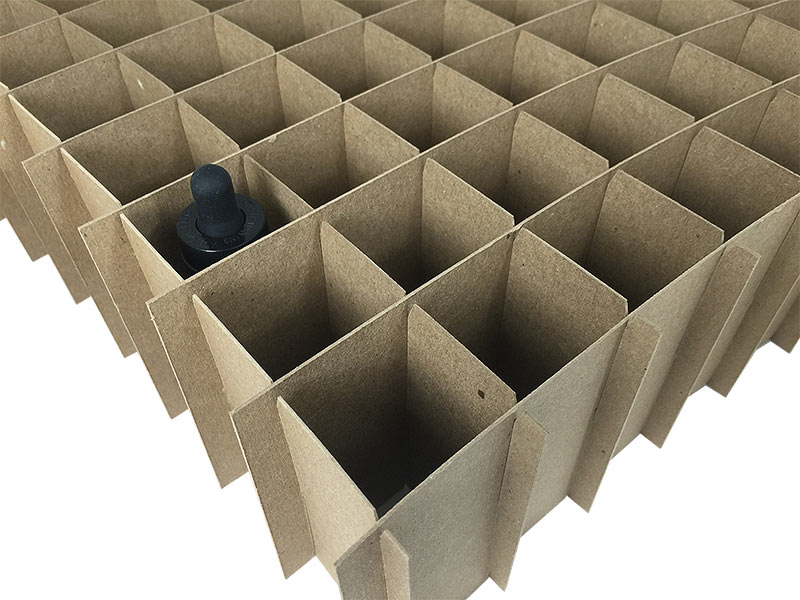

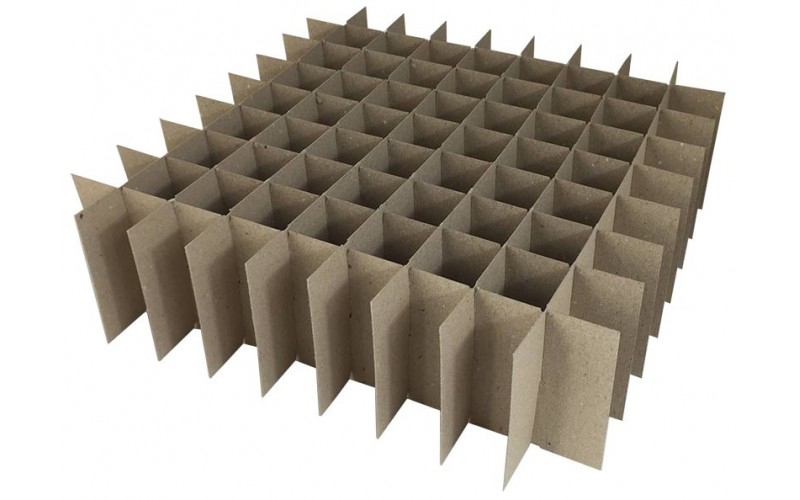

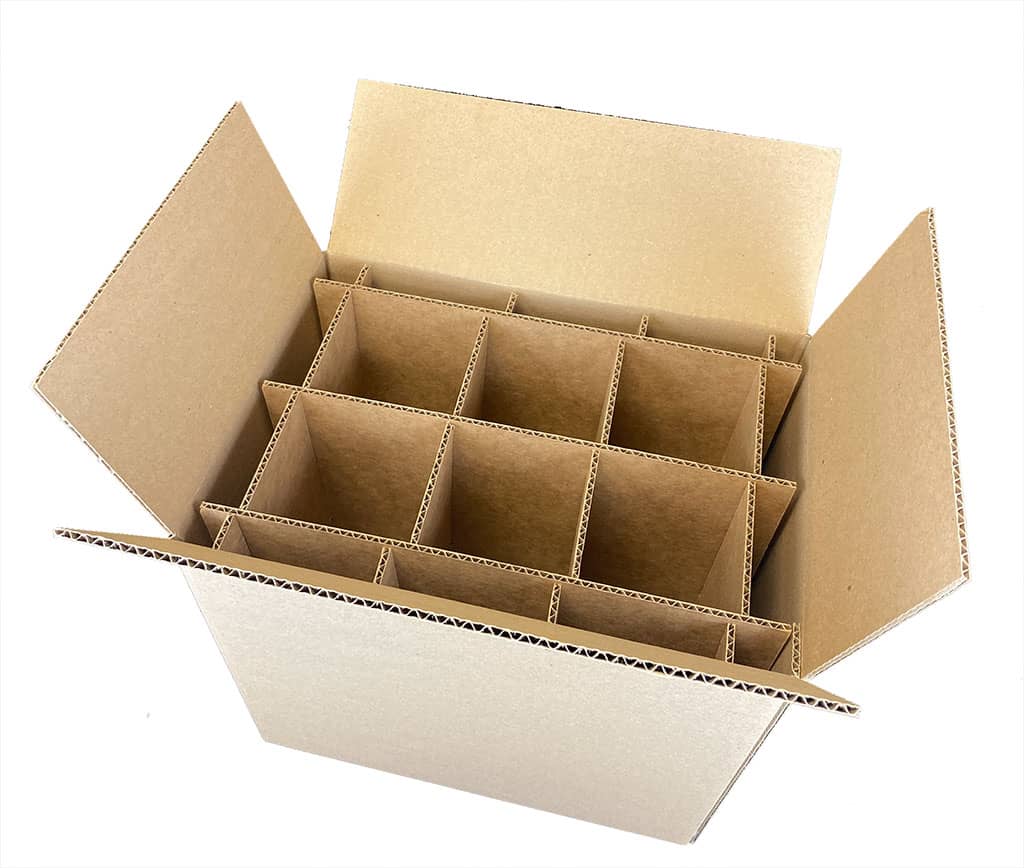

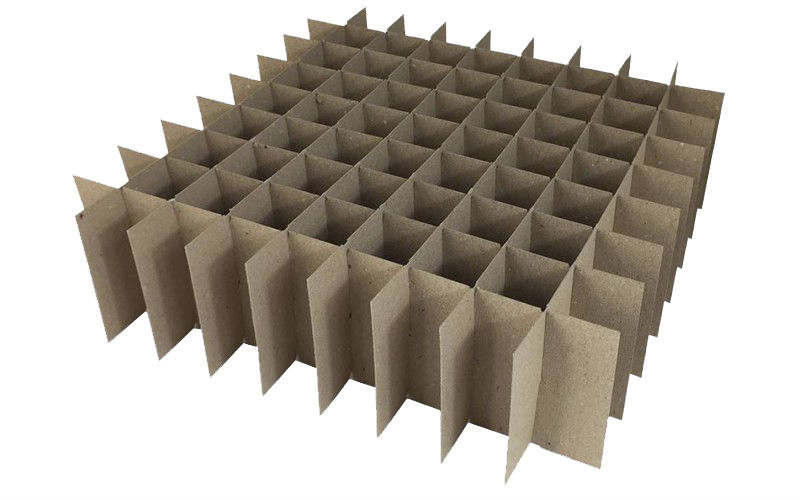

Separators serve as the guardians of fragile items during transit, preventing collisions and breakage. In the world of CBD oil packaging, where the integrity of each bottle is paramount, separators play a vital role in maintaining product quality. These components, often made from sturdy materials, create individual compartments that keep each bottle secure and stationary, minimizing the risk of damage during transportation.

Precision for Precious Contents

CBD oil, known for its therapeutic properties, requires a packaging solution that reflects the delicate nature of the product. Specialized separators are designed with precision to cradle each bottle securely. Whether it’s a glass vial or a plastic container, these separators ensure that each unit is snugly nestled within the packaging, minimizing movement and potential damage. This level of precision is crucial to preserving the potency and quality of CBD oil.

Customization for Brand Excellence

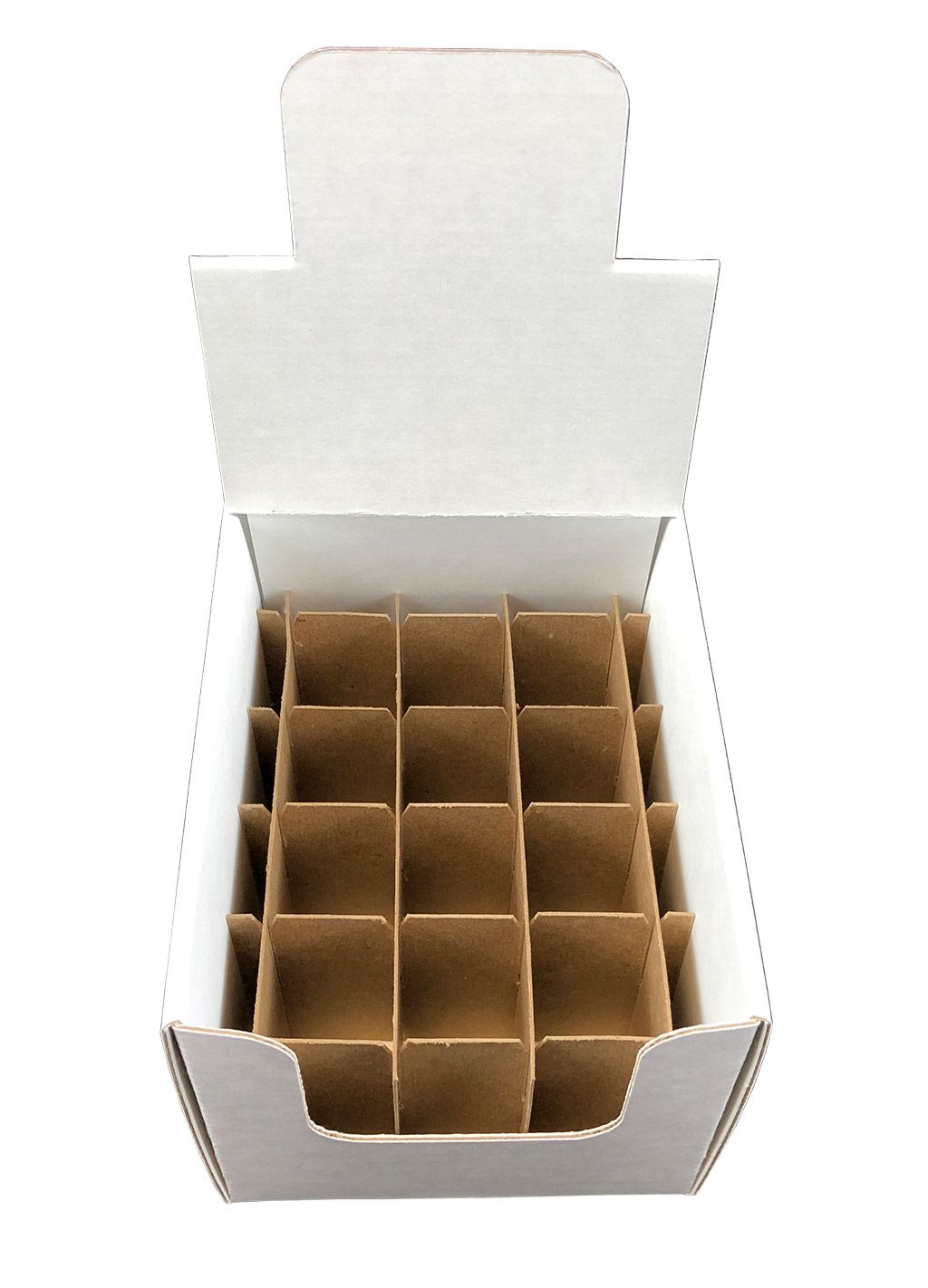

Beyond their protective function, separators contribute to the visual appeal of CBD oil packaging. Customization options allow CBD brands to incorporate separators that not only secure the bottles but also align with their brand identity. From choosing materials that complement the brand aesthetic to incorporating logos and colors, separators become an integral part of the overall packaging design, enhancing the unboxing experience for consumers.

Navigating Sustainability

In an era where environmental considerations are at the forefront, CBD oil separators are adapting to meet sustainability standards. Many packaging companies offer Eco-friendly divider options, using recycled materials or opting for biodegradable alternatives. By incorporating these Eco-conscious separators, CBD brands not only protect their products but also contribute to reducing the environmental impact of packaging materials.

As the CBD industry continues to grow, the role of separators in packaging will likely evolve to meet the changing needs of consumers and regulatory requirements. Innovations in materials, design, and sustainability will shape the future of CBD oil separators, ensuring that they remain a crucial component in the journey from production to consumer.