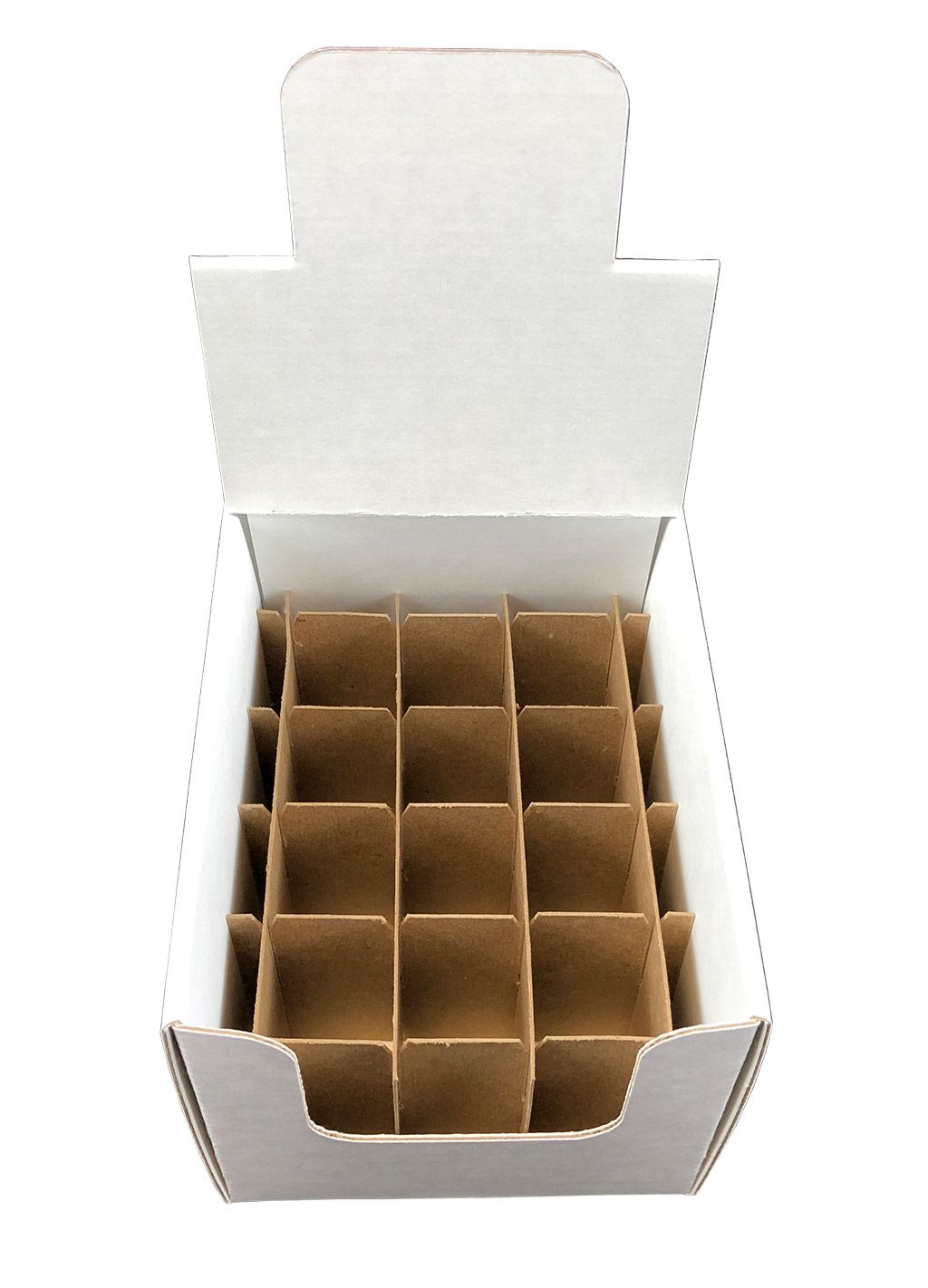

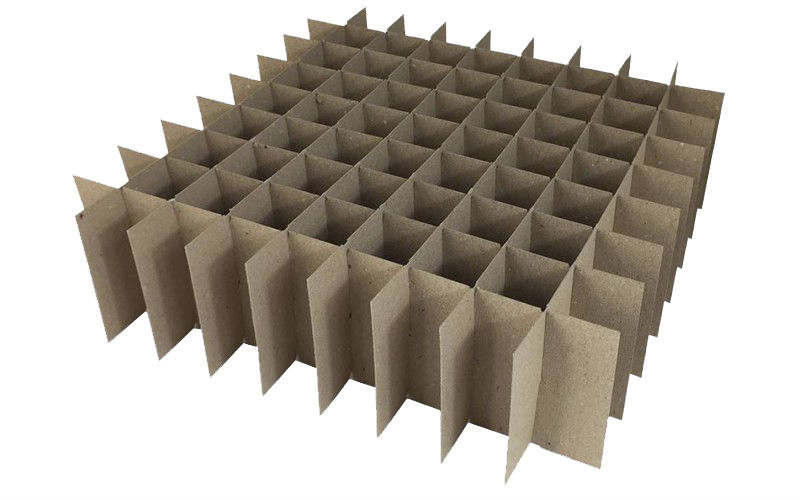

There are many different reasons that businesses are using chipboard dividers. When they are used in boxes for shipping products, they help separate the items in the box. They can protect the item from damage during shipping and storage. The use of dividers in boxes is not new, but the ones made of chipboard offer advantages that make them a better choice.

- Recycled material – Chipboard partitions are made from recycled material and are better for the planet.

- Fire protection – These dividers offer more protection from fire and heat than other partitions.

- Cost – The use of recycled material means the cost to make these dividers is less.

- More items in one box – The use of partitions allows the packer to put more items safely in a box. This can help with the costs of shipping and packaging.

These are all reasons why the business that is shipping things should consider using chipboard dividers. They are a very effective product for both big and small companies. While it is good to think about how a company can use these dividers, it may also be smart to think about how the consumer is using them as well.

Different uses

People can use the chipboard partitions in many different ways, aside from separating products in the box. They can be utilized in the home for a variety of different purposes as well. All that is required is a little imagination and a little work.

- Suitcase dividers – Travelers usually end up with a suitcase that is full of a pile of clothes and other junk. It becomes difficult to find anything, and it is hard to tell what is clean from what is dirty. A chipboard divider can be used in a suitcase to keep things separated and accessible.

- Drawer dividers – A junk drawer is a common thing to find in a home. When a divider is placed in the junk drawer, it becomes less cluttered and less junky.

- On the wall – Using a divider on the wall can provide a person with a place to display knick- knacks.

- Lunch box separators – Kids often do not like their food to touch. Keep everything separate by fitting a divider in their lunchbox.

The only limit to the ways that these dividers can be used is the imagination. If one of the advantages of a divider made of chipboard is that it comes from recycled material, then finding ways to reuse the dividers makes them even more environmentally friendly.