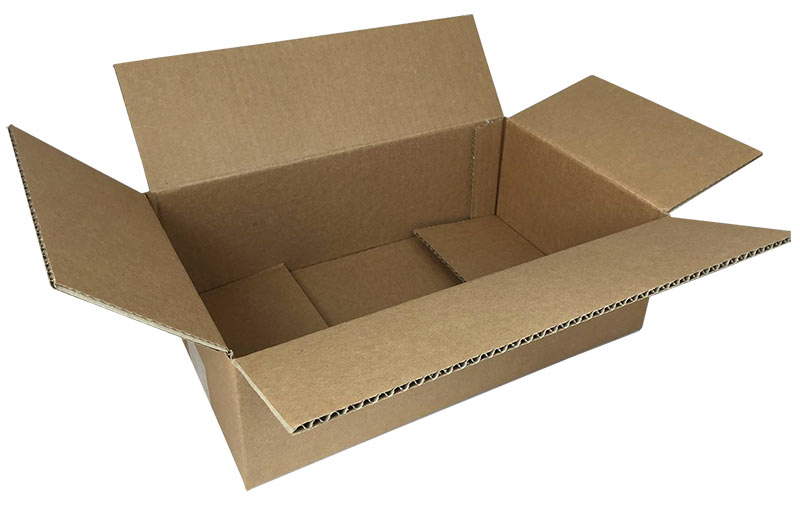

Packaging plays a critical role in ensuring products are delivered safely and efficiently. Among the most popular choices, cardboard corrugated boxes stand out for their durability, affordability, and versatility. Whether you’re shipping fragile items or storing goods, these boxes offer unmatched reliability. Paired with the strength and flexibility of a corrugated carton, businesses across industries can enhance their packaging strategies while maintaining cost efficiency.

What Makes Cardboard Corrugated Boxes Unique?

The packaging business relies heavily on corrugated boxes because of their distinctive design. They are made up of three layers: a fluted medium in between the outer and inner liners.

- Superior Strength: The fluted layer adds cushioning, making these boxes ideal for transporting heavy or fragile goods.

- Lightweight Construction: Despite their sturdiness, corrugated boxes are lightweight, reducing shipping costs.

- Eco-Friendliness: Made from recyclable materials, these boxes are an environmentally conscious packaging option.

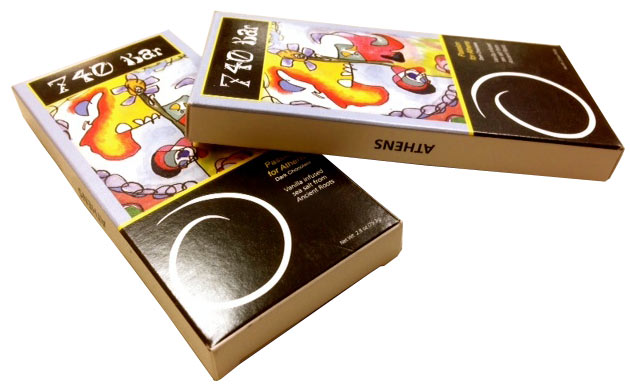

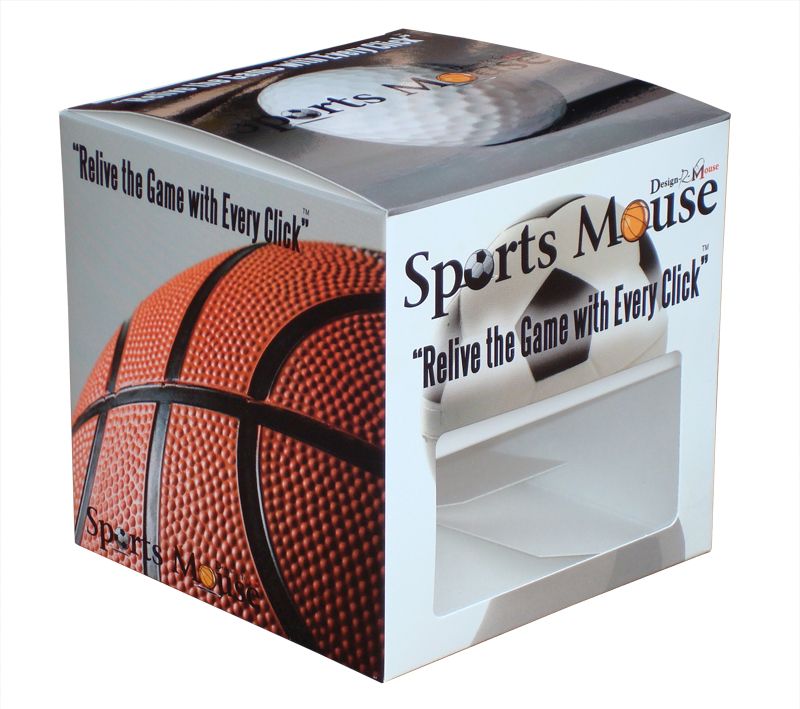

- Customization Options: Corrugated boxes can be tailored in size, shape, and printing to meet branding and product needs.

These qualities make corrugated boxes an excellent choice for businesses looking to combine functionality and sustainability.

Benefits of Using Corrugated Cartons

Corrugated cartons are more than just containers—they are essential tools for efficient logistics. Here are some of their key benefits:

- Protection: The cushioning effect of corrugated cartons protects products from damage caused by impacts, vibrations, and moisture during transit.

- Cost-Effectiveness: Affordable to produce, corrugated cartons help businesses cut packaging expenses without compromising quality.

- Versatility: From food products to electronics, corrugated cartons are suitable for a wide range of industries.

- Stackability: Their robust construction makes them easy to stack, optimizing storage and transportation space.

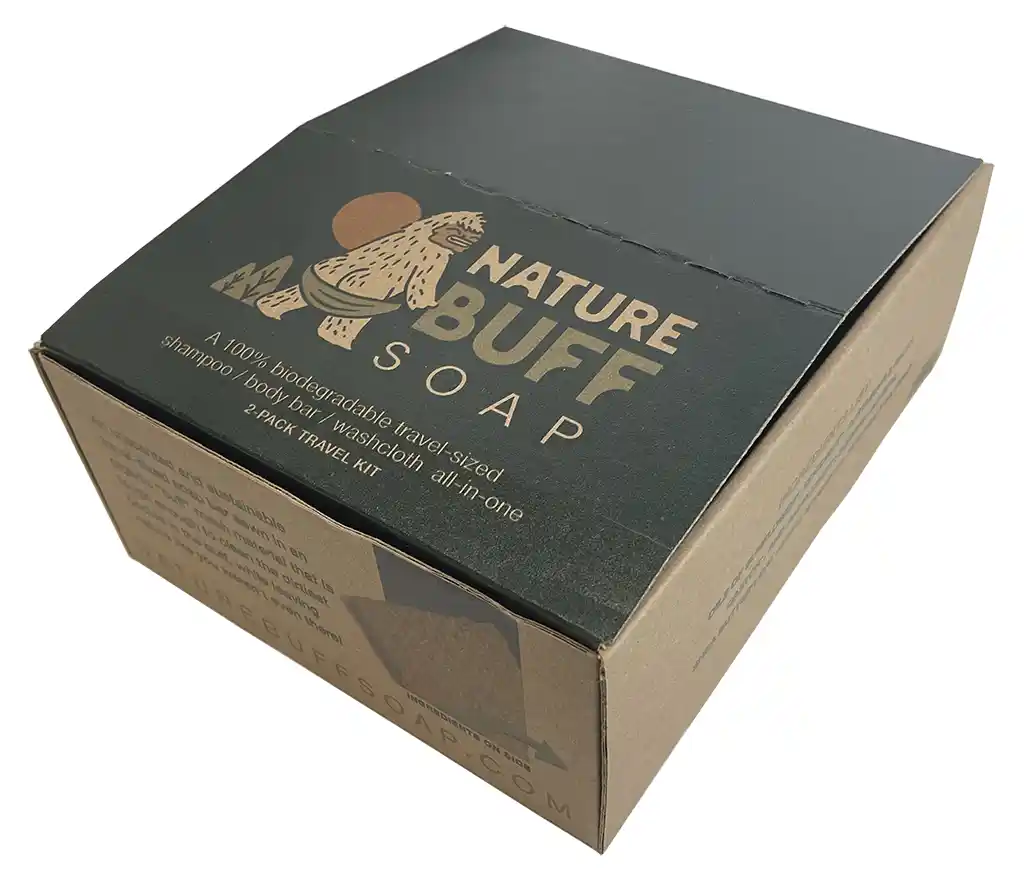

- Sustainability: As biodegradable and recyclable packaging, corrugated cartons help businesses reduce their environmental footprint.

By incorporating corrugated cartons into their packaging strategies, businesses can enhance customer satisfaction and streamline operations.

Industries That Rely on Cardboard Corrugated Boxes

Several industries rely on the versatility of corrugated boxes to meet their packaging requirements:

- E-Commerce: With the rise of online shopping, e-commerce companies use corrugated boxes to safely deliver items ranging from books to electronics.

- Food and Beverage: Corrugated packaging is widely used to transport fresh produce, beverages, and packaged foods, ensuring freshness and safety.

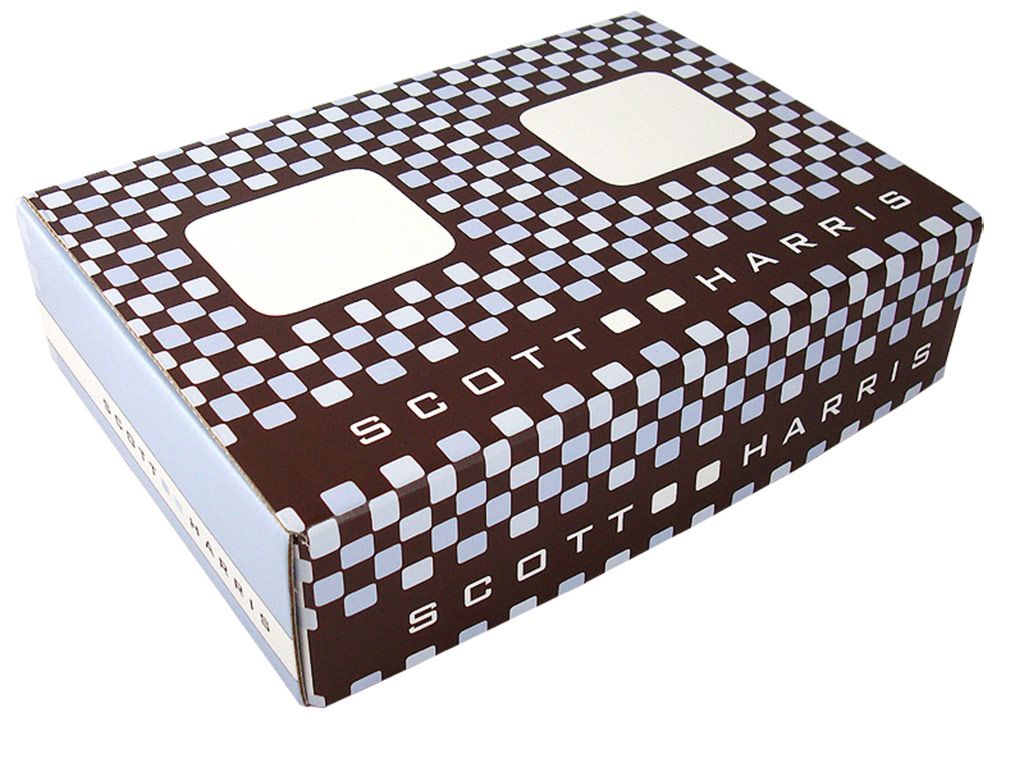

- Retail: Retailers utilize these boxes for shipping, storage, and branding through printed designs and logos.

- Electronics: The protective qualities of corrugated boxes make them ideal for fragile and sensitive electronic devices.

- Manufacturing: Factories and warehouses depend on corrugated boxes for organizing and shipping components and finished goods.

These industries demonstrate how corrugated packaging adapts to diverse needs, proving its value across the board.