When it comes to packaging solutions, corrugated fiberboard or corrugated cardboard, and its derivative, the corrugated fiber box, stand as steadfast pillars of strength, versatility, and sustainability. From safeguarding products during transit to serving as customizable branding platforms, these humble yet resilient containers play a crucial role in diverse industries worldwide.

What is Corrugated Cardboard

At the heart of every corrugated box lies corrugated fiberboard, a durable and lightweight material composed of multiple layers of paperboard sandwiched between a fluted inner layer. This unique structure provides unparalleled strength and rigidity, making corrugated cardboard an ideal choice for packaging applications requiring robust protection and cushioning. Additionally, corrugated cardboard is highly versatile and can be customized to accommodate various shapes, sizes, and printing options, allowing for endless design possibilities, and branding opportunities.

The Benefits of Corrugated Fiber Box

Corrugated fiber boxes offer a multitude of benefits that make them an indispensable packaging solution for businesses across industries. Firstly, their inherent strength and shock-absorbing properties make them ideal for protecting fragile or delicate items during shipping and handling. Whether it is electronics, glassware, or perishable goods, corrugated fiber boxes provide a reliable barrier against impacts, vibrations, and environmental factors, ensuring that products arrive at their destination in pristine condition.

Furthermore, corrugated fiber boxes are lightweight and cost-effective, helping to minimize shipping expenses and reduce carbon emissions associated with transportation. Unlike heavier packaging materials such as wood or metal, corrugated cardboard offers a favorable strength-to-weight ratio, allowing for efficient packing and stacking without compromising on protection or durability. Additionally, corrugated cardboard is recyclable and biodegradable, making it an eco-friendly choice for businesses looking to reduce their environmental footprint and embrace sustainable packaging practices.

Versatile Applications

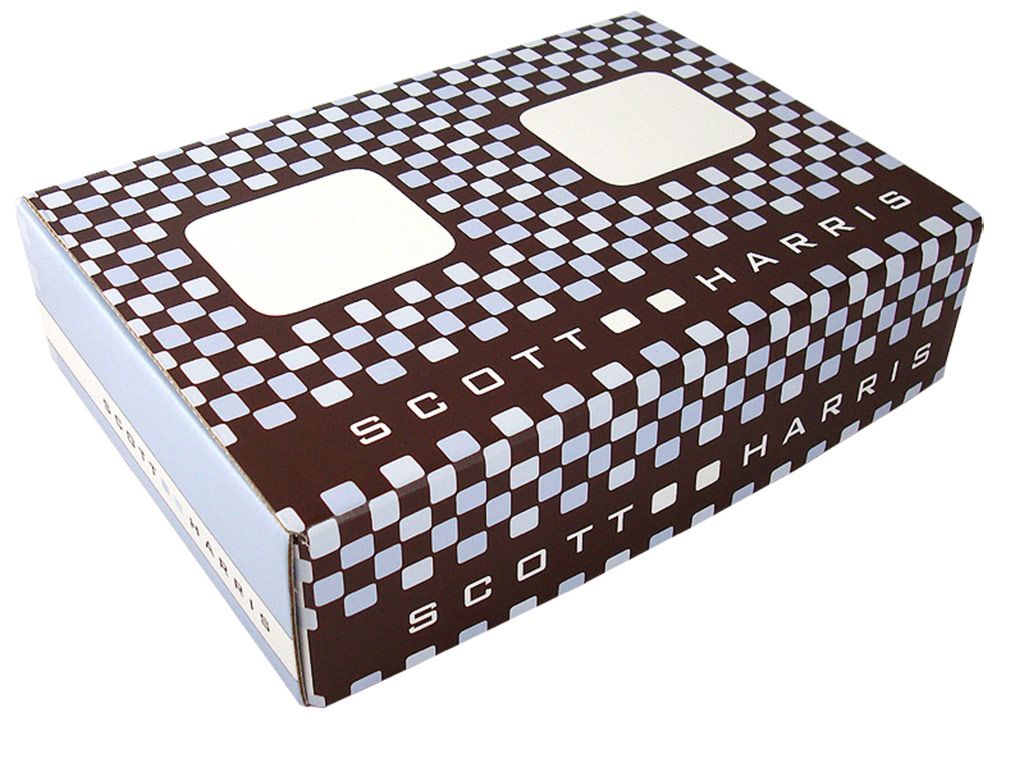

The versatility of corrugated fiber boxes extends beyond traditional shipping and packaging applications, encompassing a wide range of uses across various industries. In the retail sector, corrugated fiber boxes serve as eye-catching displays and point-of-sale packaging solutions, helping to attract customers and highlight products in-store. Whether it is a custom-designed shelf display or a branded gift box, corrugated cardboard offers endless possibilities for creating memorable brand experiences and driving sales.

Moreover, corrugated fiber boxes are also used extensively in the e-commerce industry, where online retailers rely on sturdy and secure packaging to protect products during transit. With the rise of online shopping, demand for corrugated fiber boxes has surged, prompting manufacturers to innovate and develop specialized solutions tailored to the unique requirements of e-commerce fulfillment, such as easy-to-open designs, tamper-evident closures, and integrated branding elements.