When it comes to shipping valuable items or ensuring the safe transportation of goods, choosing the right packaging is crucial. Today, we delve into the world of heavy duty shipping boxes and triple wall shipping boxes – two essential packaging solutions designed to withstand the rigors of transportation while providing ultimate protection for your items.

Understanding Heavy-Duty Shipping Boxes

Heavy-duty shipping boxes are the workhorses of the packaging industry. As the name suggests, these boxes are specifically crafted to handle bulky and weighty items. They are constructed with durable materials, such as corrugated cardboard, to withstand rough handling during transit. In this section, we’ll explore the key features of heavy-duty shipping boxes, their benefits, and the industries that benefit most from using them.

The Advantages of Triple Wall Shipping Boxes

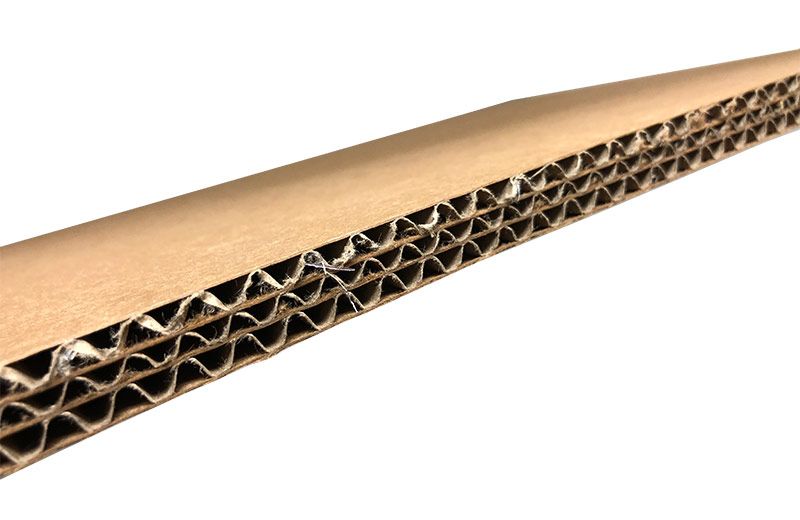

For an extra layer of protection and strength, triple wall shipping boxes come into play. These specialized boxes are engineered with three layers of corrugated cardboard, providing unparalleled sturdiness. As we delve into the advantages of triple wall shipping boxes, you’ll discover how they outperform other types of packaging and why they are a top choice for high-value and delicate items.

When to Use Heavy-Duty Shipping Boxes

Not all shipments require heavy-duty packaging, but for certain items and situations, they are an absolute necessity. In this section, we’ll discuss the specific scenarios where heavy-duty shipping boxes are indispensable. From industrial machinery to fragile artwork, understanding when to use heavy-duty packaging can save you from costly damages and ensure customer satisfaction.

Triple Wall vs. Heavy Duty Shipping Boxes: Choosing the Right Packaging

When it comes to selecting between triple wall and heavy-duty shipping boxes, the decision can be perplexing. Each type has its own set of advantages, and choosing the right one depends on various factors, including the nature of the product, transportation conditions, and budget considerations. Here, we provide valuable insights to help you make an informed choice for your packaging needs.

Heavy Duty Shipping Boxes Solutions

While the focus has been on strength and protection, it’s equally important to consider the environmental impact of the packaging we choose. In this section, we explore sustainable options for heavy-duty and triple-wall shipping boxes. From recyclable materials to Eco-friendly manufacturing practices, businesses are increasingly turning to sustainable packaging solutions to reduce their carbon footprint.

Selecting the appropriate shipping boxes is crucial to ensure your goods reach their destination intact. Whether you opt for heavy-duty shipping boxes for robust protection or triple-wall shipping boxes for maximum strength, understanding their unique benefits will help you make the right decision.