Shipping your products is one of the easiest ways to grow and expand your business considering your items can reach countless customers anywhere in the world. In order to succeed using this avenue, however, it is critical that your products are still in the best condition when they reach the client. Towards this end, you will need container solutions that will ensure the safety and protection of your items during shipping such as corrugated partitions.

Here are five reasons why using corrugated dividers when shipping your products would be beneficial for your business:

- Highly Versatile

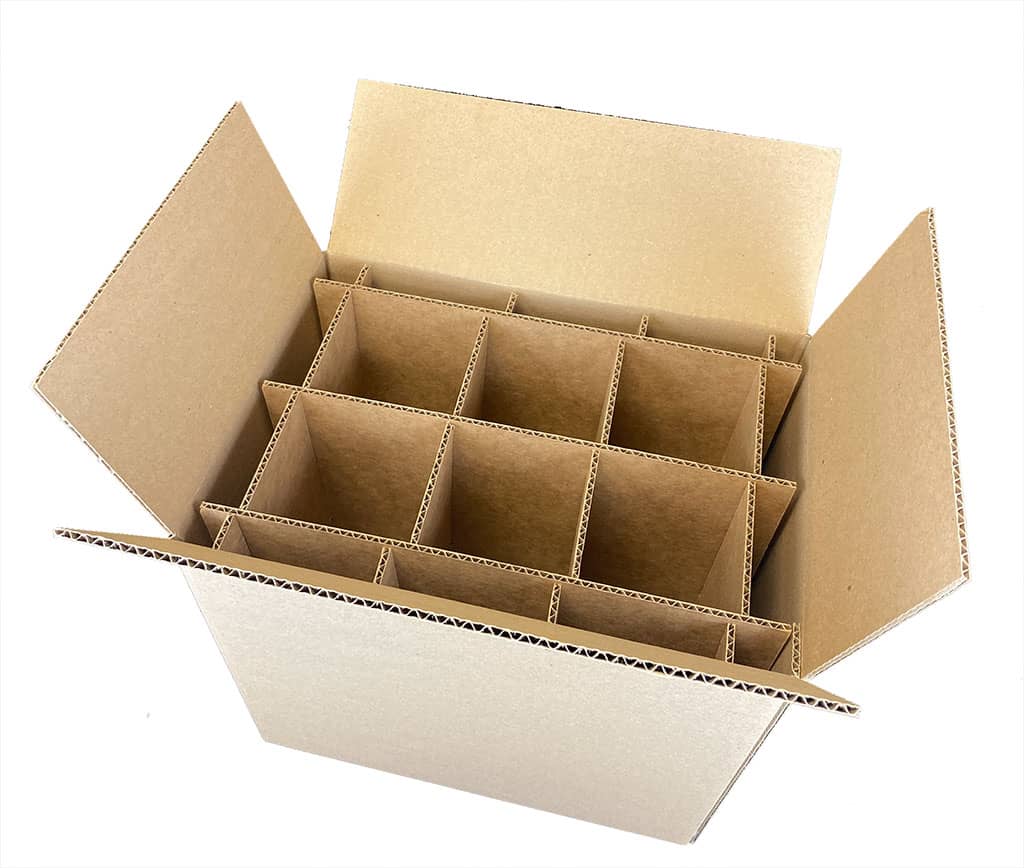

Corrugated box dividers can be used to protect a wide variety of items – from the most delicate such as glasses and small trinkets to the bulkiest such as large kitchen items. This type of partition can also endure heavy and prolong stacking since it is made with much thicker and stronger cardboard.

- Heavy Duty

Corrugated dividers are long lasting and durable because of its innate strength. Your products will be able to withstand the usual wear and blow of shipping and inappropriate handling because this type of divider provides the best cushion and protection.

- Economic

Considering that corrugated boxes and dividers are manufactured in bulk at low cost you can purchase them at the most reasonable price. This means more packaging savings for your business. Moreover, since it is made from recyclable materials it is highly sustainable and friendly to the environment.

- Customizable

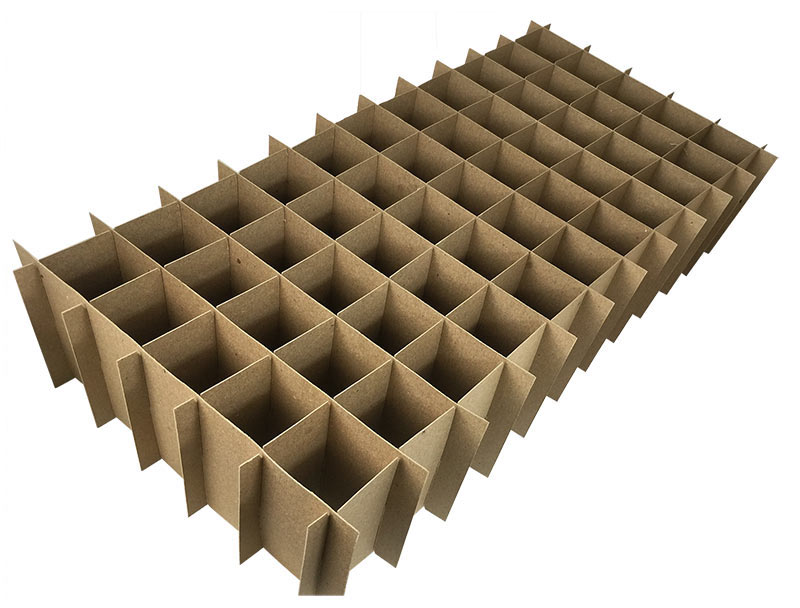

Corrugated dividers can be readily adjusted in terms of thickness, size, shape, and height, among others so that it can suit your product perfectly. They can also be treated with coatings and other solutions to make it resistant to fire and insects or be covered with printed designs of your choice. Basically, a corrugated partition can be readily customized to perfectly suit your requirements.

- Increases Aesthetic Value

Boxes with partitions do not only protect the quality of the products but it also helps to maintain the cleanliness and order of the items while inside the shipping box. The dividers also provide a more organized and cleaner look that will surely impress your customers.

Given the advantages mentioned above, it is evident that using corrugated partitions greatly protect your products from damage during shipping. Note that fiber partitions, chipboard dividers, and other similar box dividers essentially serve the same purpose. At the end of the day, box partitions will provide much-needed strength to ensure that your precious items will reach its destination in good condition.